What is SPC Rigid Core Flooring advantages?

SPC Rigid Core Flooring is 2021 Newest Pvc flooring , It has more advantages than LAMINATE WOODEN FLOORING and HARDWOODEN FLOOR.

Below is detail :

1. Green and environmental protection

The main raw material for the production of SPC Rigid Core Flooring is polyvinyl chloride. Polyvinyl chloride is an environmentally friendly and non-toxic renewable resource. It has been widely used in people's daily life, such as food bags, food containers, medical infusion tube bags, etc. , Its environmental protection is no need to worry.

2. Super wear resistance

SPC CORE FLOORING has a special PVC wear-resistant layer on the surface, and its wear-resistant revolutions can reach 80,000 revolutions. According to the different wear resistance thickness, it can be used for 5-10 years under normal conditions for commercial use and 25 years for home use. The thickness and quality of the wear layer directly determine the service life of the SPC floor. Tests show that the 0.5mm thick wear layer is ground It can be used for more than 5 years under normal commercial conditions, and the 0.7mm thick wear-resistant layer is sufficient for more than 10 years, so it is super wear-resistant. Because of its super abrasion resistance, SPC RIGID flooring is becoming more and more popular in commercial places such as hospitals, stations, airports, office buildings, shopping malls and so on with a large flow of people.

3. High elasticity and super impact resistance

RIGID CORE floor has a soft texture, so it has good elasticity. It has good elastic recovery under the impact of heavy objects. At the same time, PVC floor has strong impact resistance. It has strong elastic recovery for heavy object impact damage without causing damage. . The excellent RIGID SPC floor can minimize the damage of the ground to the human body, and can disperse the impact on the feet. The latest research data shows that after the excellent PVC floor is paved in a space with a large number of people, the personnel fall The rate of fall and injury has been reduced by nearly 70% compared to other floors.

4. Fire and flame retardant

The fire rating is B1, which means that the fire resistance is very good, second only to stone.

5. Easy maintenance

The maintenance of SPC RIGID floor is very convenient. If the floor is dirty, wipe it with a mop. Its maintenance frequency is much lower than laminate flooring and solid wood flooring.

6. Waterproof and moisture-proof

Since the main component of SPC floor is vinyl resin, it has no affinity with water, so it is naturally not afraid of water, as long as it is not soaked for a long time, it will not be damaged; and it will not be mildewed due to high humidity.

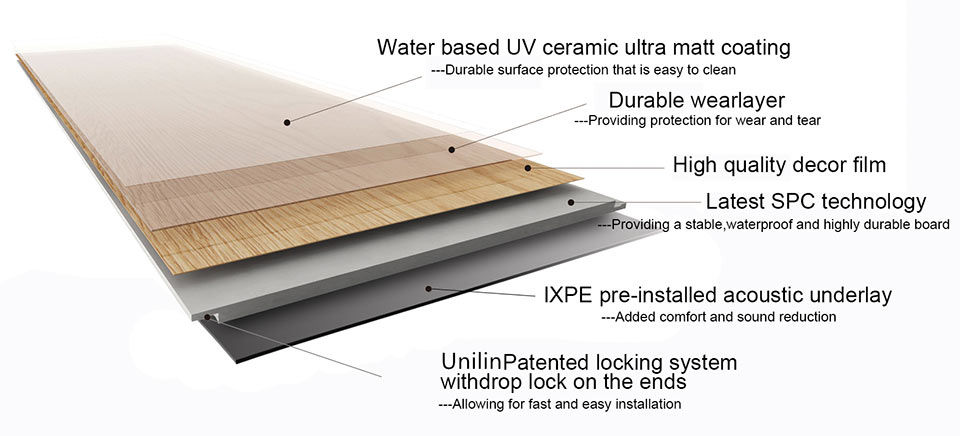

Structure

Specification

| SPC Flooring Specification | |

|

Color |

4007 |

|

Dimension |

1500*228*6mm+2mm ixpe |

|

Thickness (Optional) |

3.8mm, 4mm, 4.2mm, 5mm, 5.5mm, 6mm |

|

Wear Layer (Optional) |

0.2mm, 0.3mm, 0.5mm |

|

Size(Length*Width) (Optional) |

910*148mm, 1220*178mm, 1500*228mm, 1800*228mm, etc. |

|

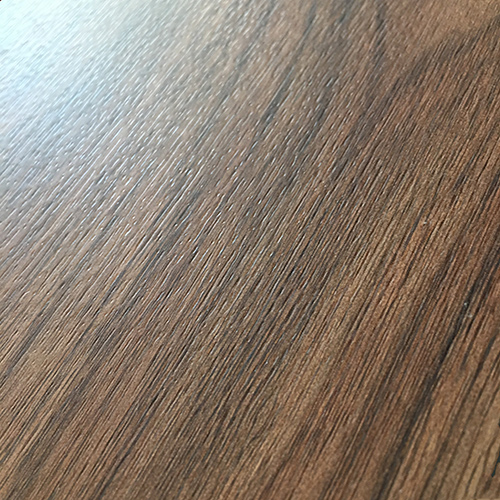

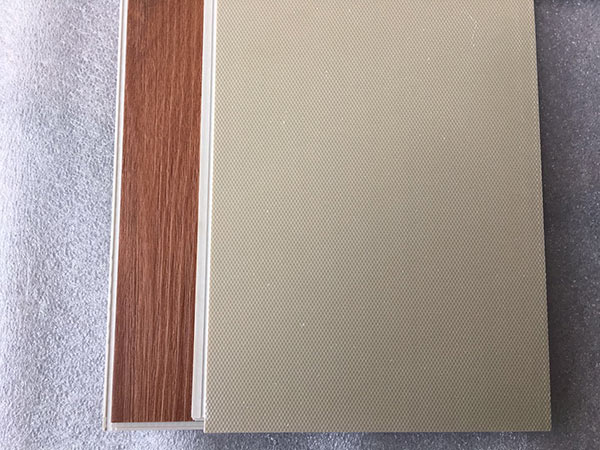

Surface (Optional) |

Crystal, Light/Deep Embossed, Real Wood, Handscraped |

|

Core Materi (Optional) |

100% virgin material |

|

Click Syste (Optional) |

Unilin Click, Valinge Lock, Drop Lock(I4F) |

|

Special treatment(Optional) |

V-Groove, Soundproof EVA/IXPE |

|

Installation Method |

Floating |

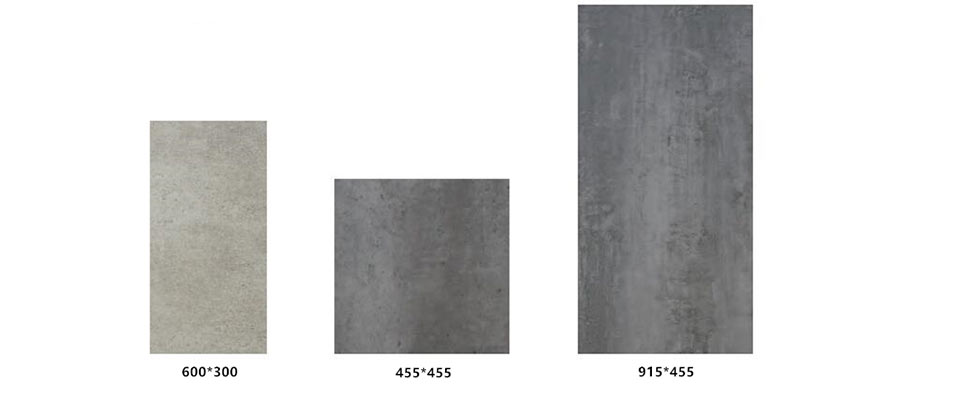

Size

A. Spc Flooring Plank

B. Spc Flooring Tile

SPC Flooring Backing

IXPE Backing

Plain EVA Backing

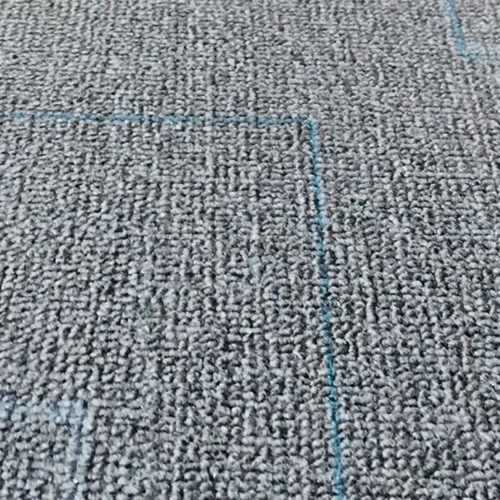

Finish Types

Carpet Surface

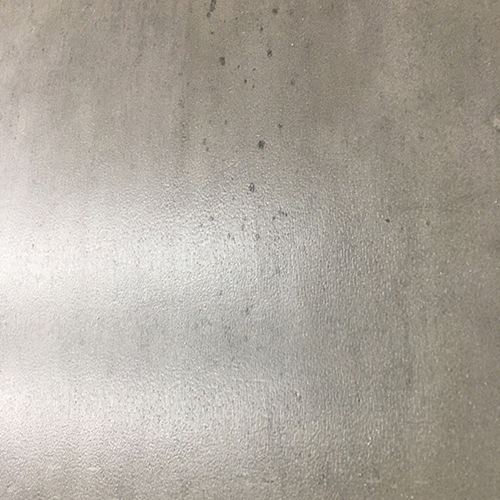

Crystal Surface

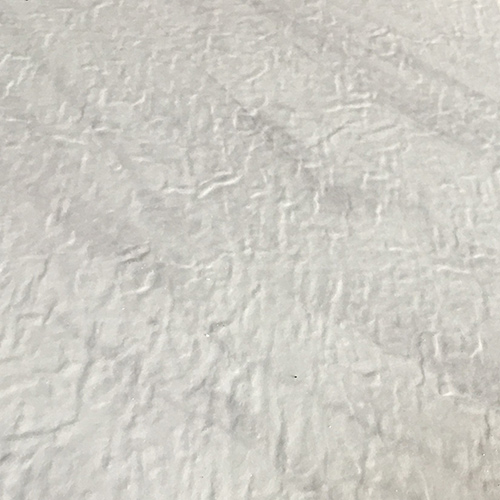

Deep Embossed Surface

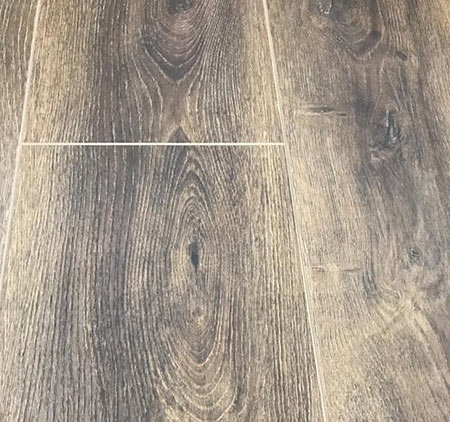

Handscraped Spc Flooring

Leather Surface

Light Embossed

Marble Surface

Real Wood

Beveled Edge Types

Micro V-Groove Beveled

V Groove Painted

What is Difference Between the 100% Virgin Spc Flooring and Recycled Spc Flooring ?

Spc Flooring Waterproof Quality Test

Unilin Click

Unilin Click 1

Unilin Click 2

SPC Floor Packing List

| SPC Floor Packing List | |||||||||

| Size | sqm/pc | kgs/sqm | pcs/ctn | sqm/ctn | ctn/pallet | pallet/20ft | sqm/20ft | ctns/20ft | Cargo Weight/20ft |

| 910×148*3.8mm | 0.13468 | 7.8 | 16 | 2.15488 | 63ctn/12pallet, 70ctn/12pallet | 24 | 3439.190 | 1596 | 27300 |

| 910×148*4mm | 0.13468 | 8.2 | 15 | 2.02020 | 63ctn/6pallet, 70ctn/18pallet | 24 | 3309.088 | 1638 | 27600 |

| 910*148*5mm | 0.13468 | 10.2 | 12 | 1.61616 | 70 | 24 | 2715.149 | 1680 | 28000 |

| 910*148*6mm | 0.13468 | 12.2 | 10 | 1.34680 | 70 | 24 | 2262.624 | 1680 | 28000 |

| 1220*148*4mm | 0.18056 | 8.2 | 12 | 2.16672 | 72ctn/10pallet, 78ctn/10pallet | 20 | 3250.080 | 1500 | 27100 |

| 1220*148*5mm | 0.18056 | 10.2 | 10 | 1.80560 | 72 | 20 | 2600.064 | 1440 | 27000 |

| 1220*148*6mm | 0.18056 | 12.2 | 8 | 1.44448 | 78 | 20 | 2253.390 | 1560 | 27900 |

| 1220*178*4mm | 0.21716 | 8.2 | 10 | 2.17160 | 75 | 20 | 3257.400 | 1500 | 27200 |

| 1220*178*5mm | 0.21716 | 10.2 | 8 | 1.73728 | 75 | 20 | 2605.920 | 1500 | 27000 |

| 1220*178*6mm | 0.21716 | 12.2 | 7 | 1.52012 | 70ctn/10pallet, 75ctn/10pallet | 20 | 2204.174 | 1450 | 27300 |

| 600*135*4mm | 0.0810 | 8.2 | 26 | 2.10600 | 72ctn/10pallet, 84ctn/10pallet | 20 | 3285.36 | 1560 | 27400 |

| 600*300*4mm | 0.1800 | 8.2 | 12 | 2.16000 | 72ctn/6pallet, 78ctn/14pallet | 20 | 3291.84 | 1524 | 27400 |

| 1500*225*5mm+2mm IXPE | 0.3375 | 10.6 | 5 | 1.68750 | 64 | 21 | 2268 | 1344 | 24500 |

| 1800*225*5mm+1.5mm IXPE | 0.4050 | 10.5 | 5 | 2.025 | 64 | 18 | 2332.8 | 1152 | 24900 |

| Remarks: The quantity per container can be adjusted according to the limited weight of container for different port. | |||||||||

Advantage

SPC Floor Anti-scracth Test

SPC Floor Fireproof Test

SPC Floor Waterproof Test

Applications

Blackbutt Spc Flooring Project in Australia – 1

Spotted Gum Spc Flooring Project in Australia – 2

SPC Floor Protection Process

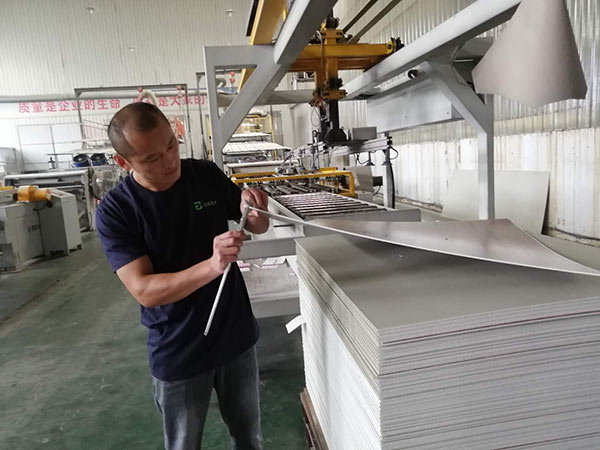

1 Workshop

4 SPC Health Board

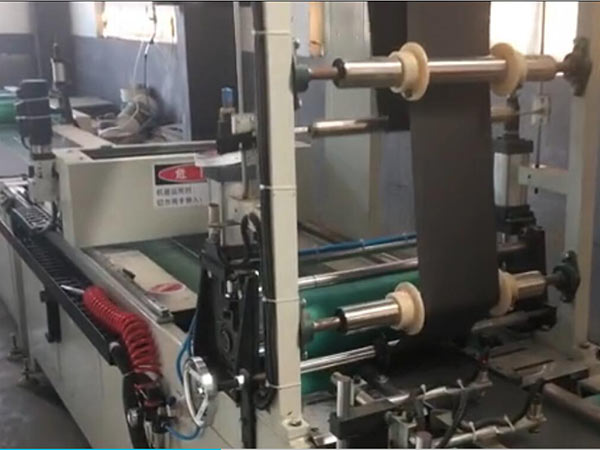

7 SPC Click Macking Machine

10 Warehouse

2 SPC Coextrusion Machine

5 SPC Quality Test

8 Foam Adding Machine

11 Loading

3 UV Machine

6 SPC Cutting Machine/strong>

9 Laboratory

A. Drop Click Spc Flooring Installation

A. Drop Click Spc Flooring Installation

B. Unilin Click Spc Flooring Installation

B. Unilin Click Spc Flooring Installation

SPC FLOORING INSTALLATION METHOD

SPC FLOORING INSTALLATION METHOD

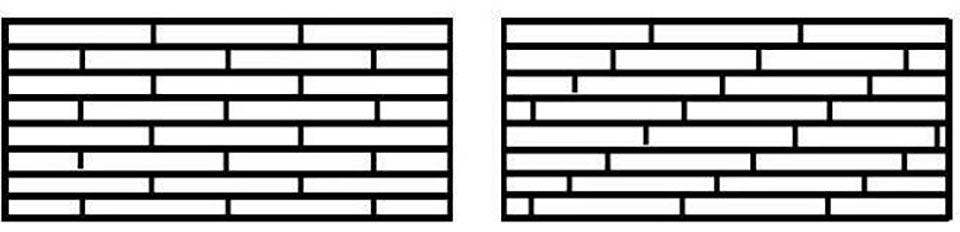

1. First, determine how you want the flooring to run. Typically for plank products, the flooring runs the length of the room. There may be exceptions since it is all a matter of preference.

2. To avoid narrow plank widths or short planks lengths near the walls/ doors, it’s important to do some pre-planning. Using the width of the room, calculate how many full boards will fit into the area and how much space remains that will need to be covered by partial planks. Divide the remaining space by two to calculate the width of the partial planks. Do the same along the length.

3. Note that the first row of planks does not need to be trimmed in width, it will be necessary to cut off the unsupported tongue so that a clean, solid edge is toward the wall.

4. 8mm expansion gaps should be kept from the wall during the installation. This will allow space the natural expansion gaps and contraction of the planks.

5. The planks should be installed from right to left. From the top right corner of the room, put the first plank in place so that both the head and side seam grooves are exposed.

6. Install the second plank in the first row by angling the short side tongue into the long side groove of the first plank.

7. To start the second row, cut a plank that is at least 152.4mm shorter than the first plank by inserting the long side tongue into the groove of the plank in the first row.

8. Install the second plank in the second row by inserting the short side tongue into the previously installed first plank long side groove.

9. Align the plank so the short side tongue tip is positioned just over the groove lip of the plank in the first row.

10. Using gentle force and at a 20-30 degree angle, push the short side tongue into the groove of the adjourning plank by sliding along the long side seam. You may need to lift the plank to the right of it slightly to allow for the “sliding” action.

11. The remaining planks can be installed in the room using the same technique. Make sure the required expansion gaps are maintained against all fixed vertical parts (such as walls, doors, cabinets etc).

12. The planks can be cut easily with a utility knife, just score the top of the plank and snap the plank in two.

Spc flooring installation design

Spc flooring installation design

| Characteristic | Test Specification and Result |

| Sizes (in inches) | 6×36; 6×48; 7×48; 8×48; 9×48; 12×24; 12×48; 12×36; 18×36 |

| Thickness | 3.8mm, 4.0mm, 4.5mm, 5.0mm, 5.5mm, 6.0mm |

| Attachment / Backing | 1.5mm or 2.0mm IXPE and EVA |

| Squareness | ASTM F2055 – Passes – 0.010 in. max |

| Size and Tolerance | ASTM F2055 – Passes – +0.016 in per linear foot |

| Thickness | ASTM F386 – Passes – Nominal +0.005 in. |

| Flexibility | ASTM F137 – Passes – ≤1.0 in., no cracks or breaks |

| Dimensional Stability | ASTM F2199 – Passes – ≤ 0.024 in. per linear foot |

| Heavy Metal Presence / Absence | EN 71-3 C — Meets Spec. (Lead, Antimony, Arsenic, Barium, Cadmium, Chromium, Mercury and Selenium). |

| Smoke Generation Resistance | EN ISO 9239-1 (Critical Flux) Results 9.1 |

| Smoke Generation Resistance, Non-Flaming Mode | EN ISO |

| Flammability | ASTM E648- Class 1 Rating |

| Residual Indentation | ASTM F1914 – Passes – Average less than 8% |

| Static Load Limit | ASTM-F-970 Passes 1000psi |

| Requirements for Wear Group pr | EN 660-1 Thickness Loss 0.30<I<0.60 prEN 660-2 Volume Los 7.5<F <15.0 |

| Slip Resistance | ASTM D2047 – Passes – > 0.6 Wet, 0.6 Dry |

| Resistance to Light | ASTM F1515 – Passes – ∧E ≤ 8 |

| Resistance to Heat | ASTM F1514 – Passes – ∧E ≤ 8 |

| Electrical Behavior (ESD) | EN 1815: 1997 2,0 kV when tested at 23 C+1 C |

| Underfloor Heating | Suitable for installing over under floor heating. |

| Curling After Exposure to Heat | EN 434 < 2mm pass |

| Recycled Vinyl Content | Approximately 40% |

| Recyclability | Can be recycled |

| Product Warranty | 10-Year Commercial & 15-Year Residential |

| Floorscore Certified | Certificate Provided Upon Request |