Video

Cov duab ntxaws

Xim Zaub

Ntev Lifespan

Kev kho qis

Tsis muaj Warping lossis Splintering

Slip-resistant taug kev nto

Scratch Resistant

Stain Resistant

Waterproof

15 Xyoo Warranty

95% recycled ntoo thiab yas

Anti-microbial

Hluav taws kub Resistant

Yooj yim Installation

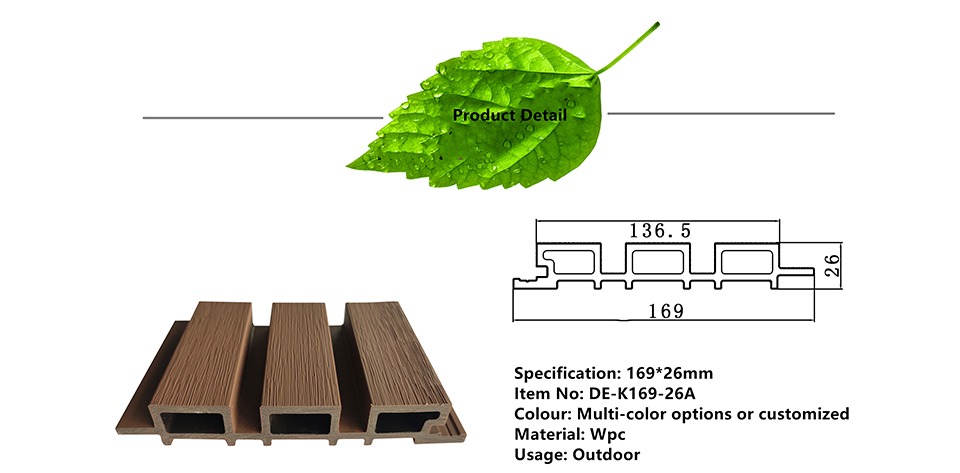

Parameter

| Hom | DEGE |

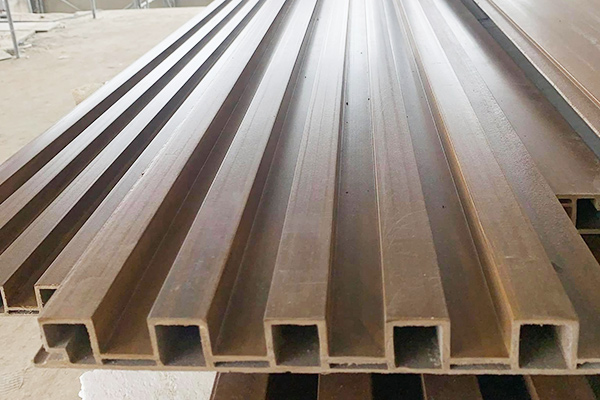

| Lub npe | WPC phab ntsa cladding |

| Yam khoom | CLADDING |

| Txheem loj | |

| WPC tivthaiv | 30% HDPE + 60% ntoo fiber ntau + 10% additives |

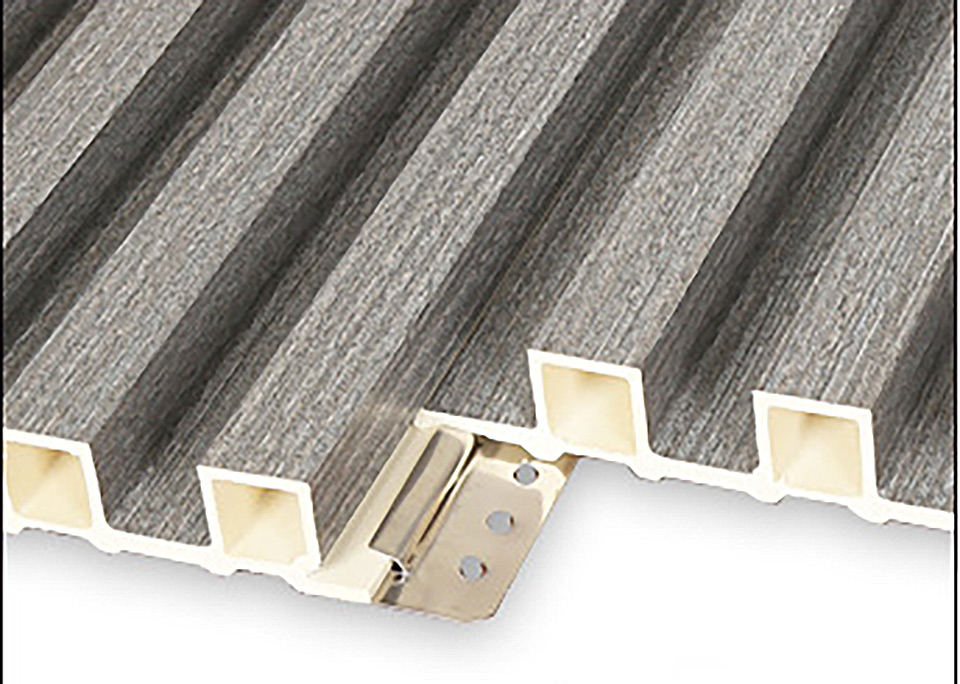

| Cov khoom siv | Patented clip-yooj yim system |

| Lub sij hawm xa tuaj | Txog 20-25 hnub rau ib lub thawv 20'ft |

| Kev them nyiaj | 30% tso nyiaj, qhov seem yuav tsum tau them ua ntej xa |

| Kev tu | Kev saib xyuas dawb |

| Rov ua dua | 100% recyclable |

| Pob | Pallet los yog bulk packing |

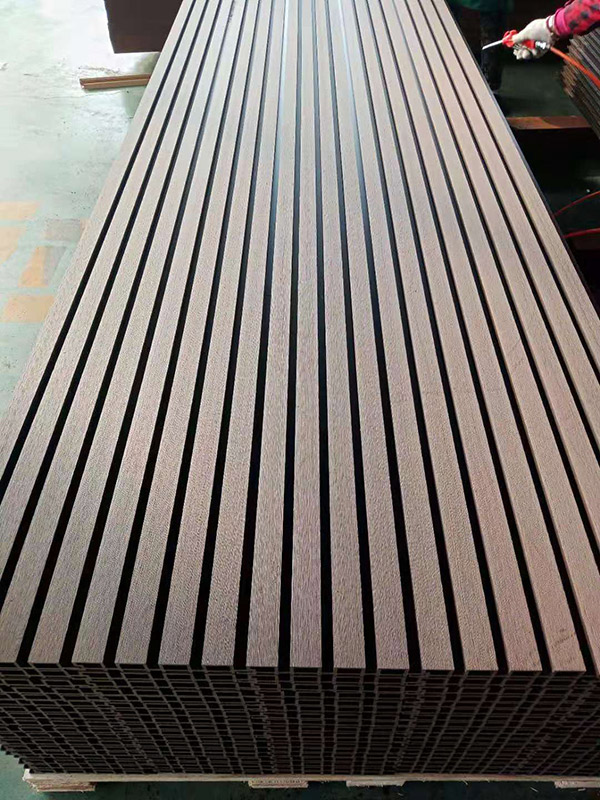

Lub Nto Muaj

Kev xeem zoo

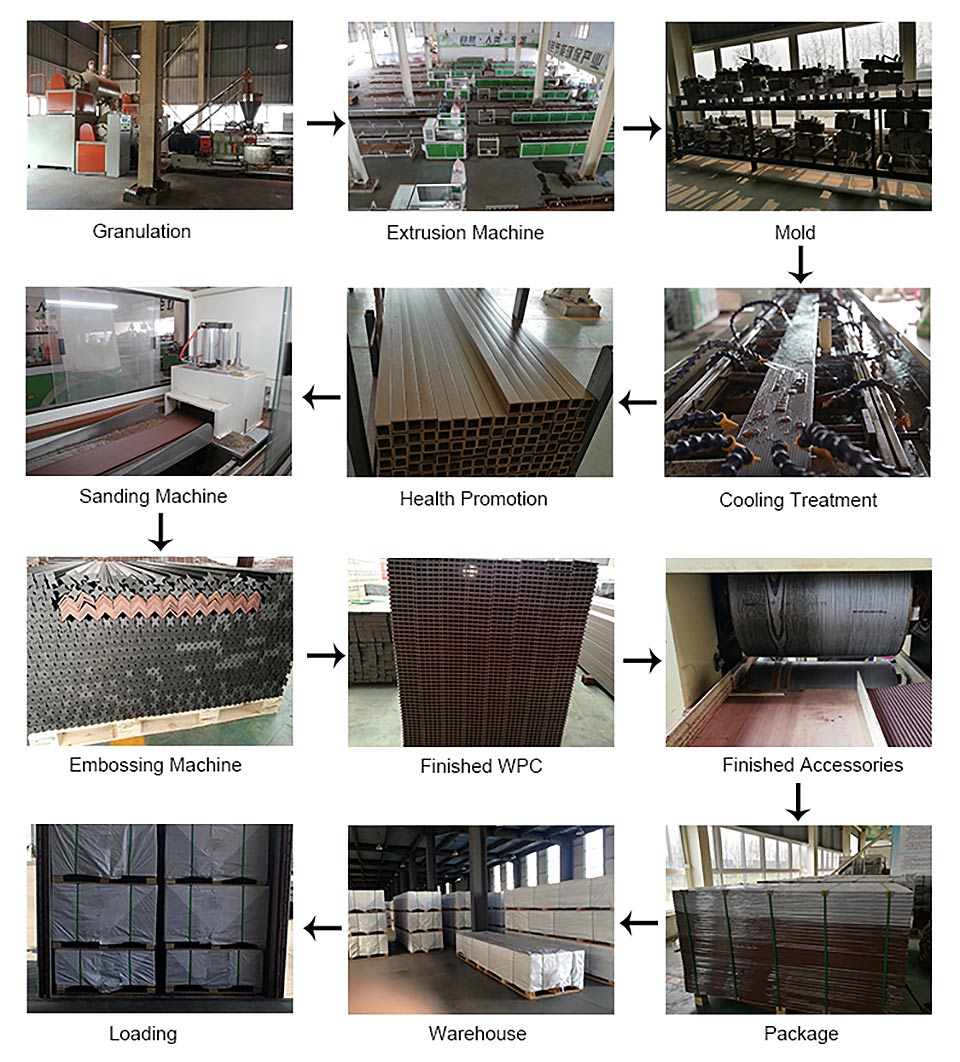

Wpc Phab Ntsa Vaj Huam Sib Luag Txheej Txheem

A. PE yas ntoo yog tam sim no siv ntau hom yas ntoo hauv ntiaj teb, uas yog, peb WPC CLADDING, WPC FENCING.Ua ntej tshaj plaws, cia peb nkag siab cov ntaub ntawv raw ntawm PE yas khoom ntoo.Cov ntaub ntawv tseem ceeb yog PE yas thiab poplar ntoo hmoov., Toner, anti-ultraviolet absorber, compatibilizer.

1. PE yas: Kev sib piv ntawm cov nqi thiab fusion HDPE yog qhov kev xaiv zoo tshaj plaws, thiab cov ntoo yas hauv kev ua lag luam yeej siv cov khoom siv rov ua dua tshiab raws li cov khoom siv tseem ceeb, uas txo cov pa phem dawb thiab ua rau peb ib puag ncig zoo thiab zoo ib puag ncig."Recycled" tseem hu ua cov khoom siv yas rov ua dua tshiab.Tag nrho cov khoom siv rov ua dua tshiab uas tuaj yeem rov qab siv dua los ntawm kev ua qee yam yog hu ua cov khoom siv rov ua dua tshiab;Cov khoom siv rov ua dua tshiab tau muab faib ua ntau qib, xws li qib tshwj xeeb cov khoom siv rov ua dua tshiab thiab cov khoom siv rov ua dua tshiab., Secondary recycling, tertiary recycling los yog khib nyiab, nws yog ib qho yooj yim to taub lub ntsiab lus, qhov siab dua qib, qhov tsawg ntawm impurity cov ntsiab lus ntawm cov yas, cov khib nyiab yog ib txwm muaj siab nyob rau hauv cov ntsiab lus impurity, thiab xaiv cov khoom raw ncaj qha. cuam tshuam rau kev xaiv ntawm cov yas ntoo Vim tias cov khoom siv yas-ntoo yog lub xeev uas cov hmoov ntoo yog qhwv nrog cov yas, yog tias cov ntsiab lus tsis huv ntawm cov yas yog siab, thiab feem ntau ntawm cov yas nws tus kheej me me, nws yog ib txwm tsis tuaj yeem qhwv cov hmoov ntoo zoo. .

2. Ntoo hmoov: Yuav kom ua tiav qhov zoo tshaj plaws fusion ntawm ntoo hmoov thiab yas hauv cov yas ntoo, tsis yog tsuas yog yuav tsum nruj me ntsis ntawm cov yas, tab sis kuj ntoo hmoov: qhov zoo tshaj plaws ntawm cov hmoov nplej ntawm tib qhov hnyav, qhov loj ntawm qhov chaw. ntawm cov hmoov.Qhov siab dua qhov kev faib ua feem ntawm cov yas yuav tsum tau;ntawm qhov tsis sib xws, qhov loj ntawm cov hmoov ntoo hmoov, qhov me me ntawm thaj tsam ntawm cov hmoov, thiab qhov qis dua ntawm cov yas xav tau thaum lub sij hawm fusion yas.Tom qab ntau xyoo ntawm kev sim, poplar ntoo hmoov yog qhov zoo tshaj plaws ntoo hmoov hmoov, thiab particle loj ntawm cov hmoov yog qhov zoo tshaj plaws nyob rau hauv lub thickness ntawm 80-100 mesh;cov hmoov zoo heev, cov nqi ua haujlwm siab, cov yas muaj pes tsawg leeg yuav tsum tau ntau dua, thiab tus nqi siab dua, tab sis cov khoom siv yas molded muaj plasticity siab dhau lawm;Yog tias cov hmoov ntxhib dhau lawm, cov nqi ua haujlwm tsawg tsawg, thiab cov khoom siv yas molded yog tsawg, tab sis cov khoom siv yas-ntoo muaj fusion tsis txaus, nkig, thiab yooj yim tawg.

3. Cov ntaub ntawv pabcuam: Lub luag haujlwm tseem ceeb ntawm toner yog kom phim cov xim ntawm cov ntaub ntawv yas ntoo.Tam sim no, daim ntawv thov tseem ceeb ntawm PE yas ntoo yog inorganic xim hmoov.Nws muaj kev tiv thaiv zoo dua rau kev siv sab nraum zoov, uas txawv ntawm cov xim organic siv rau sab hauv PVC ecological ntoo.Hmoov, organic toner xim yog vivid thiab ci.Lub luag haujlwm tseem ceeb ntawm kev tiv thaiv ultraviolet absorber yog txhawm rau txhim kho lub peev xwm los tiv thaiv ultraviolet ntawm cov yas ntoo sab nraum zoov siv, thiab txhim kho kev tiv thaiv kev laus.Compatibilizer yog ib qho additive uas txhawb kev sib raug zoo ntawm cov hmoov nplej thiab cov cob.

B. Nkag siab cov ntaub ntawv raw ntawm cov yas ntoo luv luv, cov kauj ruam tom ntej yog pelletize.Raws li cov ntaub ntawv raw li saum toj no, sib tov raws li ib qho piv txwv, extrude yas ntoo pellets los ntawm kub kub fusion ziab, thiab ntim lawv siv.Lub luag haujlwm tseem ceeb ntawm cov khoom siv pelletizing yog kom paub txog cov txheej txheem ua ntej-plasticization ntawm cov hmoov ntoo thiab cov yas, paub txog kev sib xyaw ntawm biomass hmoov cov khoom thiab PE yas nyob rau hauv melting tej yam kev mob, thiab ua pretreatment rau zus tau tej cov ntaub ntawv yas ntoo.Vim yog qhov tsis zoo ntawm cov ntoo-yas yaj, qhov tsim ntawm cov khoom siv ntoo-yas pelletizer thiab yas pelletizer tsis zoo ib yam.Rau cov yas sib txawv, qhov tsim ntawm cov pelletizer kuj txawv.Cov pelletizer feem ntau yog siv rau polyethylene feem ntau siv conical twin-screw extruder, vim hais tias polyethylene yog ib tug kub-rhiab resin resin, thiab conical ntxaib-ntsia hlau extruder muaj zog shearing quab yuam thiab cov ntsia hlau ntev yog sib npaug.Lub ntxaib ntsia hlau extruder yog luv luv, uas txo cov sijhawm nyob ntawm cov khoom hauv lub thoob.Sab nraud txoj kab uas hla ntawm cov ntsia hlau muaj ib tug conical tsim los ntawm loj mus rau me me, yog li cov compression ratio yog heev loj, thiab cov khoom yuav ua tau plasticized ntau tshaj thiab uniformly nyob rau hauv lub chim.

C. Tom qab pelletizing, nws nkag mus rau theem extrusion.Ntau qhov kev npaj yuav tsum tau ua ua ntej extrusion:

1. Xyuas kom tseeb tias tsis muaj impurities lossis cov khoom ntawm lwm cov xim uas tseem tshuav nyob rau hauv lub hopper kom tsis txhob muaj xim tsis huv ntawm cov ntoo yas tsim;

2. Tshawb xyuas seb cov khoom siv lub tshuab nqus tsev ntawm lub extruder tsis muaj kev cuam tshuam thiab xyuas kom meej tias lub tshuab nqus tsev kawm ntawv tsis tsawg dua -0.08mpa.Lub tshuab nqus tsev yuav tsum tau ntxuav ob zaug ib zaug yog tias nws zoo li qub.Tsis txhob siv cov cuab yeej hlau los ntxuav lub qhov tso pa tawm, thiab siv cov yas los yog ntoo los ntxuav cov impurities hauv cov qhov tso pa ntawm lub thoob;

3. Xyuas seb lub hopper puas tau nruab nrog lub tshuab lim hlau.Cov khoom yog lim los ntawm cov hlau kom tshem tawm cov hlau impurities sib xyaw hauv cov khoom, txo qhov hnav ntawm cov hlau impurities nyob rau hauv cov khoom siv thiab xyuas kom meej fusion ntawm molded yas-ntoo profiles.

4. Txawm tias lub tshuab dej txias ua haujlwm zoo li cas.Cov dej txias zoo tshaj plaws yog cov cuab yeej tsim nyog rau kev txias tom qab yas-ntoo extrusion.Kev kho cua txias raws sijhawm tuaj yeem ua kom cov duab zoo ntawm cov yas-ntoo profiles.

5. Txhim kho cov yas-ntoo pwm, thiab nruab cov pwm tsim raws li cov profiles yuav tsum tau ua.

6. Xyuas seb lub tshuab txiav pneumatic thiab lwm yam ntsia hlau puas tuaj yeem ua haujlwm tau zoo.

D. Qhov kub ntawm qhov tshiab extruded yas-ntoo profile yog qhov siab, thiab nws yuav tsum tau manually muab tso rau hauv ib lub tiaj tiaj.Tom qab qhov profile tau txias tag, nws yuav ua tiav thiab ntim.Txawm hais tias cov kauj ruam no yooj yim, nws tseem ceeb heev.Yog tias lub Hoobkas tsis quav ntsej cov ntsiab lus no, cov khoom siv hauv lub Hoobkas feem ntau yuav muaj qhov tsis xws luag.Cov ntoo yas tsis sib xws yuav yooj yim ua rau cov thicknesses sib txawv ntawm qhov chaw sab saud thiab qis ntawm cov khoom tom qab kev sib tsoo thiab kev ua haujlwm tom qab.Tsis tas li ntawd, qhov tsis sib xws ntawm cov profiles yuav ua rau muaj kev nyuaj rau kev tsim kho thiab cuam tshuam rau cov nyhuv toj roob hauv pes.

E. Raws li kev xav tau ntawm cov neeg siv khoom, txheej txheem yas-ntoo profiles:

1. Kev kho kev sib tsoo yog tshem tawm ib txheej ntawm cov tawv nqaij uas tsim thaum cov yas-ntoo profile yog extruded, kom cov yas-ntoo profile tau zoo dua hnav tsis kam thaum ntsia ntawm lub hoobkas.

2. Kev kho mob embossing: Tom qab qhov saum npoo ntawm qhov profile yog polished, cov yas-ntoo yog embossed ua rau saum npoo ntawm cov yas-ntoo profile muaj cov nyhuv zoo li ntoo.

3. Txiav, tenoning ua, customized loj raws li cov neeg siv khoom xav tau, thiab cov khoom customized xws li tenoning xav tau.

4. Tom qab ua tiav cov txheej txheem saum toj no, cov kauj ruam kawg yog los ntim cov khoom.Kev ntim khoom tsim nyog tuaj yeem txo qhov kev puas tsuaj los ntawm cov khoom thaum lub sijhawm xa khoom.

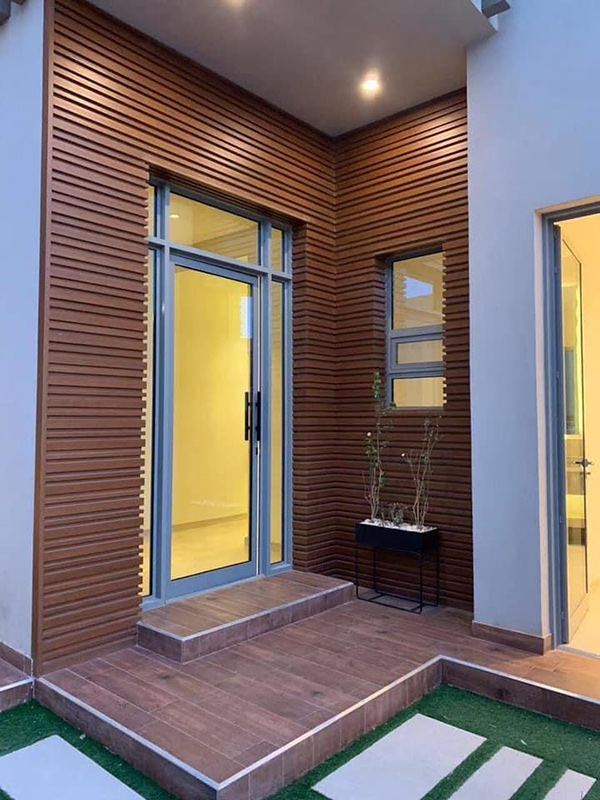

Engineering Case

Engineering Case 2

Ua ntej:nruab keel ua ntej, Keel tuaj yeem yog ntoo lossis Wpc

Thib ob:kho lub vaj huam sib luag sab nraum zoov ntawm lub keel nrog hlau buckle

Thib peb:kho cov hlau buckle thiab keel nrog ib rab phom cua ntsia hlau lossis ntsia hlau

Plaub:Tom qab ntxig rau sab nraum zoov wpc phab ntsa vaj huam sib luag rau sab sauv vaj huam sib luag xauv, siv cov ntsia hlau ntsia hlau los yog ntsia hlau los kwv yees cov hlau buckle thiab keel.

Thib tsib:rov ua kauj ruam plaub

Rau:Tom qab ua tiav cov phab ntsa vaj huam sib luag, ntxiv L edge bands ib ncig

| Qhov ntom | 1.33g / m3 (Standard: ASTM D792-13 Txoj Kev B) |

| Tensile zog | 24.5 MPa (Standard: ASTM D638-14) |

| Flexural zog | 34.5Mp (Standard: ASTM D790-10) |

| Flexural Modulus | 3565Mp (Standard: ASTM D790-10) |

| Kev cuam tshuam lub zog | 84J / m (Standard: ASTM D4812-11) |

| Ntug hardness | D71 (Standard: ASTM D2240-05) |

| Kev nqus dej | 0.65% (Standard: ASTM D570-98) |

| Thermal expansion | 33.25 × 10-6 (Standard: ASTM D696 - 08) |

| Slip resistant | R11 (Standard: DIN 51130: 2014) |