Carbonized xyoob pem teb

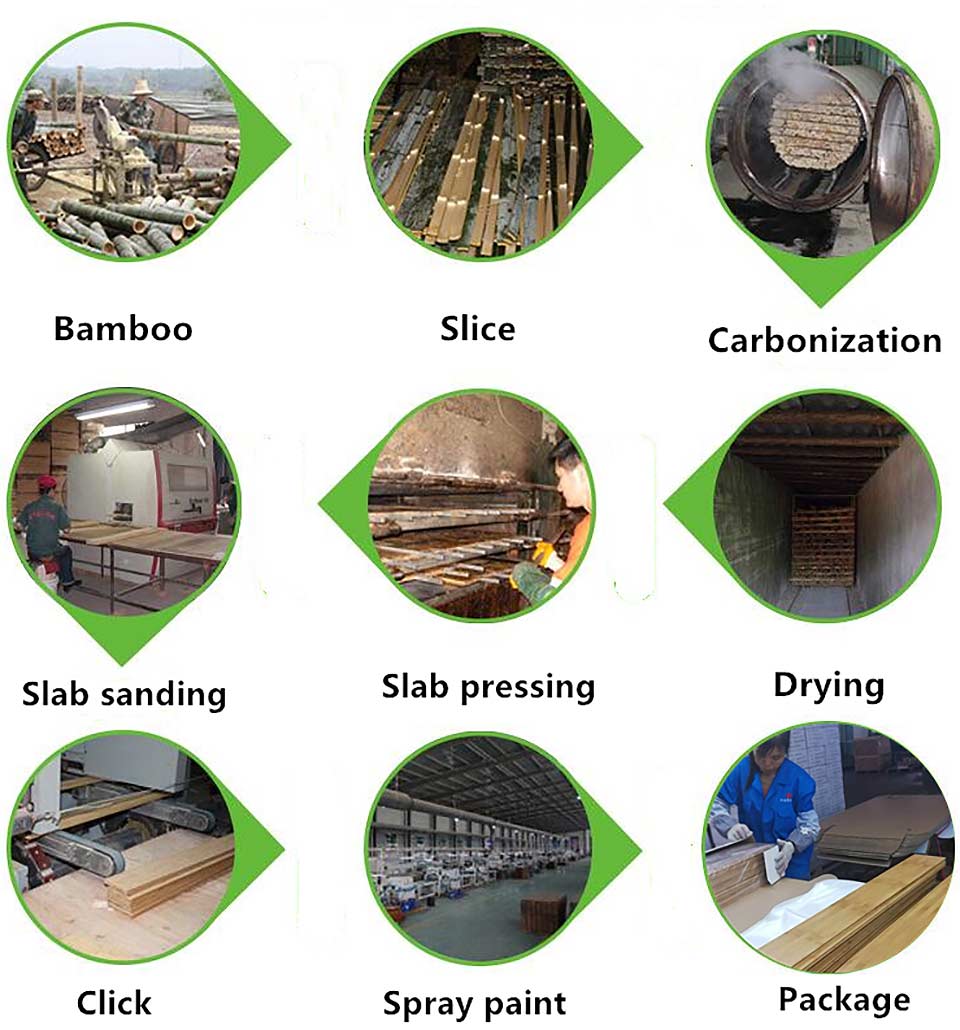

Cov txheej txheem ntau lawm xyoob hardwood flooring?

A.Brief qhia txog xyoob flooring txheej txheem:

Moso xyoob → txiav tawm → du cov pob qij txha sab nrauv → qhib lub strips → tshem tawm cov pob qij txha sab hauv → npaj ob sab ntawm cov xyoob strips (kom tshem tawm cov xyoob ntsuab thiab xyoob daj) → steaming (tiv thaiv kab thiab tshuaj tiv thaiv kab mob) los yog Carbonized coloring kev kho mob → ziab → xyoob zoo npaj → Xyoob sawb sorting → Gluing → Sib dhos blanks → Kub xovxwm bonding → Sanding → Taag ntev txiav → Plaub-sided planing (taw dav, rov qab zawj) → ob-kawg milling (kab rov tav thiab longitudinal tenoning ) → Spraying ntug xim → Plain board sanding → sorting → plua plav tshem tawm → dej-raws li primer → cua kub ziab → putty → UV curing → primer → UV curing → sanding → primer → UV curing → sanding → top coat → UV curing → khawb tiv thaiv Cov xim tiav → UV kho → tshuaj xyuas → ntim

B.Detailed piav txog xyoob flooring ntau lawm txheej txheem:

1.Raw xyoob tshuaj xyuas

Bamboo flooring feem ntau siv moso xyoob ua cov khoom siv raw, tab sis cov khoom siv ntawm moso xyoob yog ze ze rau xyoob xyoob thiab qhov chaw ntawm cov khoom.Lub hnub nyoog ntawm xyoob yog tsawg dua 4 xyoos, qhov degree ntawm lignification ntawm lub hauv paus ntawm xyoob yog tsis txaus, lub zog yog tsis ruaj, thiab qhuav shrinkage thiab o tus nqi yog loj.Xyoob laus dua 5 xyoos yuav tsum tau siv.Xyoob feem ntau muaj cov hauv paus hniav tuab thiab nyias nyias.Yog li ntawd, moso bamboos tshiab nrog cov rods ncaj nrog ib txoj kab uas hla ntawm lub mis siab tshaj 10cm thiab phab ntsa thickness ntau dua 7 hli feem ntau yog siv los ua raw khoom.

2.Khoom tawg

Moso xyoob muaj cov cag tuab thiab nyias saum.Cov raj xyoob yog qhov txawv raws li qib ntawm phab ntsa tuab thiab txiav rau hauv qhov ntev ntev.

3. xuas nrig ntaus

Ntxuav cov xyoob nyoos rau hauv cov xyoob tsis tu ncua

4 thawj txoj kev npaj

Tom qab ziab, cov xyoob strips yuav tsum tau npaj rau txhua sab rau kev npaj zoo rau txhua sab kom tshem tawm cov seem xyoob ntsuab, xyoob daj thiab cov cim ntawm cov riam uas sab laug los ntawm kev npaj ntxhib.Tom qab qhov kev kho mob no, xyoob strips thiab xyoob strips tuaj yeem ua kom ruaj khov yam tsis muaj kab nrib pleb., Tsis muaj cracking, tsis muaj delamination.Cov xyoob strips yuav tsum tau txheeb xyuas tom qab kev npaj zoo, thiab cov xyoob strips uas tsis ua raws li qhov yuav tsum tau ua ntawm qhov loj me thiab muaj xim loj sib txawv raug tshem tawm ntawm cov kab ntau lawm.

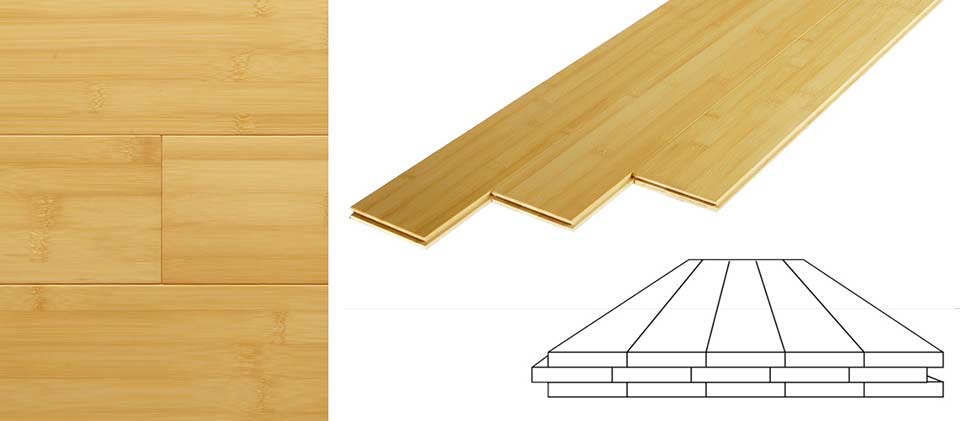

Kev kho mob ua ntej ntawm qhov saum npoo ntawm xyoob strips.Qhov saum npoo yog shaved thiab yellowed, uas yog, xyoob daim tawv nqaij thiab nqaij raug tshem tawm, thiab tsuas yog nruab nrab tuab fiber txheej yog khaws cia.Cov khoom siv xyoob tsoos tau ua tiav los ntawm kev khoov tag nrho cov khoom siv xyoob cylindrical rau hauv cov ntawv sau.Nws tsis tau npaj kom tshem tawm cov daj.Cov xyoob ntsuab rau ntawm qhov chaw, uas yog, qhov ntom ntawm cov tawv nqaij xyoob yog qhov sib txawv ntawm cov fiber ntau crude, thiab cov shrinkage deformation tus nqi nyob rau hauv tib yam qhuav humidity sib txawv, yog li nws yog ib qho yooj yim mus ua cracking.Xyoob daj yog ib feem ntawm xyoob nqaij nyob rau hauv lub puab phab ntsa ntawm lub xyoob raj.Nws muaj cov suab thaj siab thiab lwm yam khoom noj, thiab nws yooj yim rau cov kab loj hlob yog tias nws tsis raug tshem tawm.

Nyob rau hauv cov nqe lus ntawm thickness, lub flexural lub zog ntawm xyoob nws tus kheej yog siab tshaj ntawm cov ntoo, thiab 15 hli tuab xyoob flooring muaj txaus flexural, compressive thiab cuam tshuam lub zog, thiab muaj ib tug zoo txhais taw.Qee cov tuam ntxhab, txhawm rau txhawm rau ua kom cov neeg siv khoom xav tau tias cov tuab tuab zoo dua, lawv tsis tshem cov ntsuab lossis daj.Tom qab cov nplooj ntawv xyoob yog glued, txawm hais tias lub thickness ntawm lub xyoob pem teb tuaj yeem ncav cuag 17mm lossis 18mm, lub zog sib txuas tsis zoo thiab nws yooj yim tawg.Rau qhov zoo xyoob flooring, xyoob ntsuab thiab daj xyoob ntawm ob sab ntawm xyoob yog roughly planed.Txhawm rau ua kom cov xyoob blanks nruj nreem kaw, lawv yuav tsum tau npaj kom zoo.Lub thickness thiab dav tolerances yuav tsum tau tswj nyob rau hauv 0.1 hli., Cov nplaum siv rau kev sib txuas xyoob blanks kuj tseem tuaj yeem ua kom ruaj khov nyob rau hauv qhov kev txiav txim siab kub, thiab cov adhesion muaj zog heev.5. Ua noj tshuaj dawb lossis carbonization

Cov tshuaj muaj pes tsawg leeg ntawm xyoob yog yeej ib yam li cov ntoo, feem ntau yog cellulose, hemicellulose, lignin thiab extractive tshuaj.Txawm li cas los xij, xyoob muaj protein ntau, qab zib, hmoov txhuv nplej siab, rog, thiab siv quav ciab ntau dua li ntoo.Nws yog yooj yim eroded los ntawm kab thiab fungi thaum qhov kub thiab av noo tsim nyog.Yog li ntawd, xyoob strips yuav tsum tau siav tom qab rough planing (natural xim).) Los yog kub-kub thiab high-humidity carbonization kev kho mob (xim xim av) kom tshem tawm ib co extracts xws li qab zib thiab starch, ntxiv cov tshuaj tua kab, preservatives, thiab lwm yam los tiv thaiv kev yug me nyuam ntawm kab thiab fungi.

Lub ntuj xim pem teb yog bleached nrog hydrogen peroxide ntawm ib tug kub ntawm 90 ℃, thiab lub sij hawm bleaching yog txawv rau txawv keeb kwm nrog txawv phab ntsa thickness.3.5 teev rau 4 ~ 5 hli, 4 teev rau 6 ~ 8 hli.

Cov pa roj carbon-xim av yog ua tiav los ntawm cov txheej txheem carbonization thib ob nyob rau hauv qhov kub thiab txias.

Qhov thib ob carbonization tshuab carbonizes tag nrho cov as-ham xws li qe, rog, qab zib, thiab cov protein nyob rau hauv xyoob, ua rau cov khoom teeb, thiab xyoob fibers yog teem nyob rau hauv ib tug "hollow cib" zoo, uas zoo heev txhim kho lub tensile, compressive zog thiab waterproof. kev ua tau zoo.

5. Qhuav

Cov dej noo ntawm xyoob chips tom qab steaming kev kho mob tshaj 80%, mus txog lub xeev saturated.Cov dej noo ntawm xyoob ncaj qha cuam tshuam rau kev ruaj ntseg ntawm cov khoom tiav thiab cov duab tom qab xyoob ua.Txhawm rau kom ntseeg tau tias cov khoom siv xyoob flooring zoo, cov khoom siv xyoob raw khoom siv rau kev ua haujlwm yuav tsum tau ua kom qhuav ua ntej gluing.Xyoob ziab yog ua los ntawm kev ziab kiln los yog taug qab ziab kiln.

Cov dej noo ntawm cov ntaub ntawv xyoob yuav tsum tau tswj raws li kev nyab xeeb hauv cheeb tsam thiab kev siv ib puag ncig.Piv txwv li, cov dej noo tswj nyob rau sab qaum teb thiab sab qab teb ntawm Tuam Tshoj yog txawv.Cov dej noo ntawm cov khoom siv nyob rau sab qaum teb yog tsawg heev, thiab yuav tsum tau tswj ntawm 5-9% nyob rau hauv ib txwm muaj xwm txheej.

Cov dej noo ntawm txhua chav tsev uas ua rau hauv pem teb xyoob, uas yog lub xyoob sawb, yuav tsum ua kom zoo ib yam.Piv txwv li, xyoob hlua hauv pem teb (paj phaj) yuav tsum muaj cov ntsiab lus noo noo ntawm xyoob strips ntawm qhov chaw, nruab nrab thiab hauv qab txheej, kom nws tsis yooj yim rau deform thiab khoov tom qab xyoob pem teb yog tsim.

Qhov no kuj yog qhov txuas tseem ceeb los tiv thaiv hauv pem teb los ntawm kev tawg.Cov ntsiab lus tsis sib xws lossis cov dej noo ntau dhau tuaj yeem ua rau hauv pem teb deform lossis tawg vim kev hloov ntawm ib puag ncig xws li kub thiab qhuav av.Cov ntsiab lus noo noo tuaj yeem tsim raws li huab cua av noo nyob rau hauv ntau qhov chaw.Lub hauv pem teb ua nyob rau hauv txoj kev no tuaj yeem lav kom yoog raws li kev nyab xeeb ib puag ncig.

Cov hauv pem teb zoo tau dhau mus rau qhov kev ntsuam xyuas ntau lub ntsej muag thaum ziab kom ntseeg tau tias txhua daim ntawm xyoob strips, nrog rau cov ntsiab lus noo ntawm cov xyoob strips, nto thiab sab hauv, yog sib npaug, thiaj li ua kom ntseeg tau tias cov pem teb tawg thiab deforms vim txawv vaum ib puag ncig.Nws yog ib qho nyuaj rau cov neeg siv khoom los ntsuas cov dej noo.Txoj kev nyab xeeb dua los daws qhov teeb meem no yog xaiv cov chaw tsim khoom muaj npe nrov thiab niaj hnub xyoob flooring uas tuaj yeem tsim cov slabs.

6.kev npaj zoo

Xyoob strips yog finely npaj rau qhov yuav tsum tau specifications.

7.Kev xaiv khoom

Txheeb cov xyoob strips rau hauv ntau qib.

8.Gluing thiab repressing

Cov kua nplaum thiab cov khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob

Kub-nias thiab gluing: Kub-nias yog txheej txheem tseem ceeb.Nyob rau hauv qhov tshwj xeeb siab, kub thiab lub sij hawm, lub slab yog glued mus rau hauv ib tug dawb paug.Qhov nto tiav ntawm cov xyoob strips, cov nplaum nplaum thiab cov kub nias muaj qhov cuam tshuam zoo rau kev sib txuas ntawm lub xyoob pem teb.

Lub zog sib txuas ntawm xyoob flooring yog txawv ntawm cov ntoo flooring.Nws yog tsim los ntawm gluing thiab nias ntau daim ntawm xyoob.Qhov zoo ntawm cov kua nplaum, qhov kub thiab txias ntawm cov kua nplaum thiab lub sij hawm ntawm kev txuag hluav taws xob thiab lub siab tag nrho muaj kev cuam tshuam rau qhov zoo ntawm cov kua nplaum.Lub zog sib txuas tsis txaus tuaj yeem deform thiab tawg.Txoj hauv kev yooj yim los ntsuas qhov kev sib khi lub zog yog tsau los yog ua noj ib qho hauv pem teb hauv dej.Sib piv cov qib ntawm kev nthuav dav, deformation thiab qhib thiab lub sijhawm xav tau.Txawm hais tias xyoob pem teb yuav deformed los yog degummed muaj kev sib raug zoo nrog lub zog sib txuas.

9.Txiav taub hau

10.Kev tshuaj xyuas board xim sib cais

11.Txiav

12.Trimming yog poj niam tenon

13.Thaum tsim los tiv thaiv tenon board, lub taub hau luv yuav tsum tig ib ncig

14.Sanding

Kho qhov chaw ntawm lub slab kom ua kom lub ntsej muag du, thiab txhim kho lub thickness ntawm lub tiaj slab

15.Tenoning

Moulders

Hauv qab thiab sab ntawm lub rooj tsavxwm xyoob yog tenoned.

Ob chav kawg tenoning

Xyoob pem teb yog tenoned vertically thiab horizontally.

Tenoning kuj feem ntau hu ua slotting, uas yog concave-convex notch thaum lub hauv pem teb yog spliced, uas yog tus yuam sij los xyuas kom meej lub zoo meej splicing ntawm hauv pem teb.Qhov sib txawv ntawm ob pem teb yog nruj thaum lub mortise yog precision spliced.

16.Xim

Txhawm rau tiv thaiv kom tsis txhob ya raws hauv ib puag ncig los ntawm kev nkag mus rau hauv pem teb xyoob, thiab ua kom lub board nto muaj kev tiv thaiv kev ua qias tuaj, ua kom tsis muaj zog, thiab kho kom zoo nkauj, yuav tsum tau pleev xim rau hauv pem teb xyoob.Feem ntau tom qab 5 primers (lacquer) thiab 2 sab (lacquer) txheej, qhov saum npoo ntawm xyoob pem teb tau npog nrog cov xim pleev xim tuab.Lub hardness ntawm cov xim zaj duab xis tsis yog qhov nyuaj dua, nws yuav tsum yog nruab nrab ntawm hardness kom ntseeg tau tias cov xim zaj duab xis muaj qee qhov kev hnav tsis kam, khawb tsis kam thiab toughness.

Xim rau saum npoo ntawm xyoob pem teb.Pem teb ntawm kev ua lag luam muab faib ua ci thiab semi-matt.Qhov ci ntsa iab yog cov txheej txheem txheej txheej txheej, uas zoo nkauj heev, tab sis nws lub ntsej muag tau hnav thiab tev tawm, yog li nws yuav tsum tau ua tib zoo saib xyuas thaum siv nws.Cov matt thiab semi-matt yog cov txheej txheem txheej txheej, nrog cov xim mos thiab cov xim muaj zog adhesion.

Muaj tsib lub hauv qab thiab ob sab, xya hauv qab thiab ob sab hauv khw.Xaiv cov xim zoo nkauj zoo nkauj thiab ib puag ncig zoo thaum siv cov primer, uas tuaj yeem tsis tsuas yog ua kom muaj kev noj qab haus huv hauv tsev, tab sis kuj ua tiav kev zoo nkauj, dej tsis kam, thiab tiv thaiv kab mob.Txhawm rau kom cov xim zoo adhesion, ib txheej ntawm cov xim yuav tsum tau sanded.Tom qab rov ua xuab zeb thiab pleev xim, qhov saum npoo ntawm hauv pem teb yog du thiab tiaj tus yam tsis muaj npuas.

17.Kev tshuaj xyuas cov khoom tiav

Tshawb xyuas cov khoom tiav.Adhesion, nto nyhuv, abrasion kuj thiab gloss.

Txhawm rau kom ntseeg tau qhov kev txiav txim siab zoo ntawm hauv pem teb, European thiab Asmeskas kev lag luam siv kev tshuaj xyuas zaj duab xis, thiab ntau lub tuam txhab hauv tsev tseem siv cov cuab yeej tshuaj xyuas no.Tau kawg, tus txheeb ze tus nqi siab dua

Qauv

Ntuj Xyoob Flooring

Carbonized Xyoob Flooring

Ntuj Carbonized Xyoob Pem Teb

Xyoob Flooring Advantage

Cov duab ntxaws

Xyoob Flooring Technical Data

| 1) Cov khoom siv: | 100% Raw Bamboo |

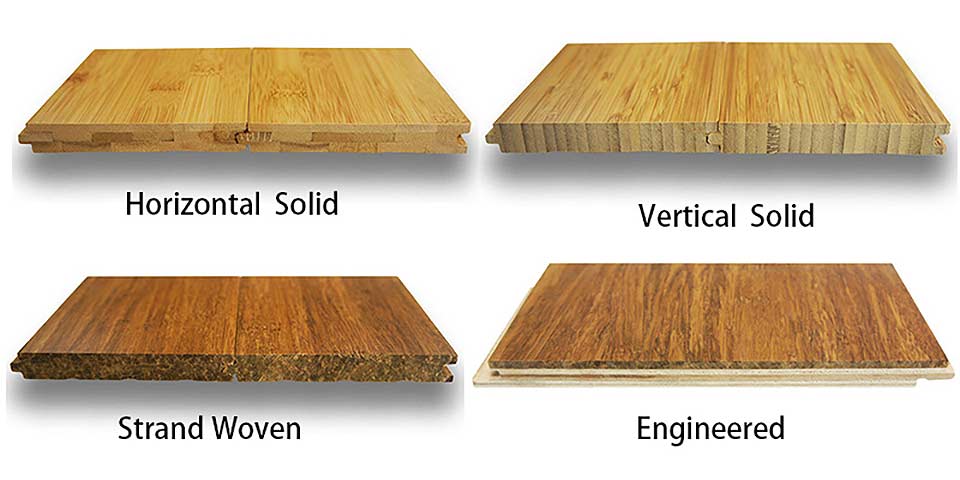

| 2) Xim: | Strand Woven |

| 3) Loj: | 1840 * 126 * 14mm/ 960 * 96 * 15mm |

| 4) Cov dej noo: | 8% -12% |

| 5) Formaldehyde emission: | Mus txog E1 tus qauv ntawm Tebchaws Europe |

| 6) Varnish: | Treffert |

| 7) Kua nplaum: | Dynea |

| 8) Glossiness: | Matt, Semi gloss |

| 9) Qhov sib txawv: | Tus nplaig & Groove (T&G) nyem.Unilin + Tso nyem |

| 10) Muaj peev xwm muab khoom: | 110,000 m2 / hli |

| 11) Daim ntawv pov thawj: | Daim ntawv pov thawj CE, ISO 9001: 2008, ISO 14001: 2004 |

| 12) Ntim: | Cov yeeb yaj kiab yas nrog lub thawv ntawv |

| 13) Lub sij hawm xa tuaj: | Hauv 25 hnub tom qab tau txais cov nyiaj them ua ntej |

Nyem System Muaj

A: T&G Nyem

T&G LOCK BAMBOO-Bamboo Florinig

Xyoob T&G - Bamboo Florinig

B: Tso (sab luv) + Unilin nyem (ntev sab)

poob xyoob Florinig

unilin Xyoob Florinig

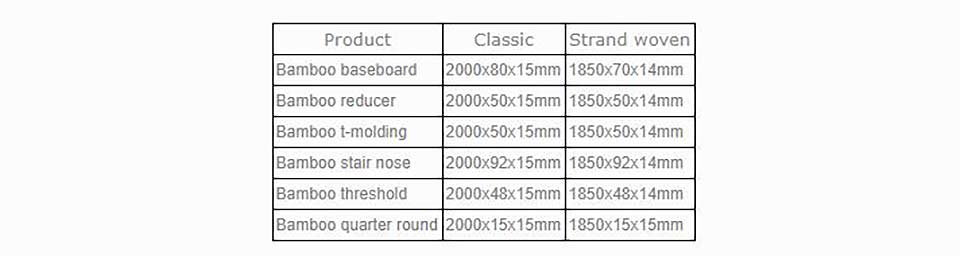

Xyoob flooring pob ntawv

| Hom | Loj | Pob | Tsis muaj Pallet / 20FCL | Pallet / 20FCL | Qhov loj ntawm lub thawv | GW | NW |

| Carbonized xyoob | 1020 * 130 * 15mm | 20pcs / ctn | 660 ctns / 1750.32 sqm | 10 plt, 52 ctns / plt, 520 ctns / 1379.04 sqms | 1040 * 280 * 165 | 28 kqb | 27kq ua |

| 1020 * 130 * 17mm | 18pcs / ctn | 640 ctns / 1575.29 sqm | 10 plt, 52 ctns / plt, 520 ctns / 1241.14 sqms | 1040 * 280 * 165 | 28 kqb | 27kq ua | |

| 960 * 96 * 15mm | 27pcs / ctn | 710 ctns / 1766.71 sqm | 9 plt, 56ctns / plt, 504ctns / 1254.10 sqms | 980 * 305 * 145 hli | 26 kqb | 25 kqb | |

| 960 * 96 * 10mm | 39pcs / ctn | 710 ctns / 2551.91 sqm | 9 plt, 56ctns / plt, 504ctns / 1810.57 sqm | 980 * 305 * 145 hli | 25 kqb | 24 kqb | |

| Strand Woven Xyoob | 1850 * 125 * 14mm | 8pcs / ctn | 672 ctn, 1243.2 sqm | 970 * 285 * 175 hli | 29kg ua | 28 kq | |

| 960 * 96 * 15mm | 24pcs / ctn | 560 ctn, 1238.63 sqm | 980 * 305 * 145 hli | 26 kq | 25 kg ib | ||

| 950 * 136 * 17mm | 18pcs / ctn | 672 ctn, 1562.80 sqm | 970 * 285 * 175 hli | 29kg ua | 28kg ua |

Ntim

Dege Brand Ntim

Ntim Ntim

Kev thauj mus los

Cov txheej txheem khoom

Daim ntawv thov

Yuav ua li cas yog xyoob pem teb ntsia (ntau yam version)

Yuav ua li cas yog xyoob pem teb ntsia (ntau yam version)

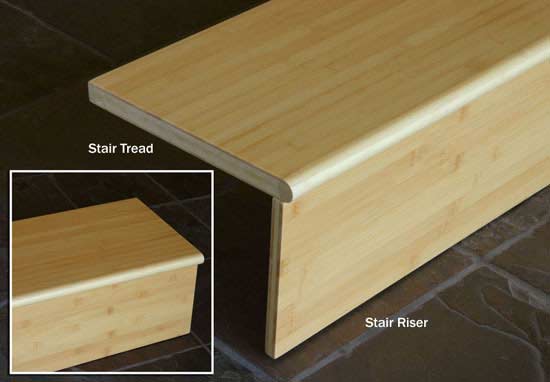

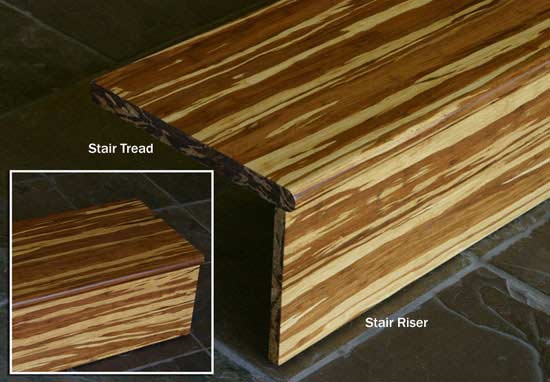

Stair slab

Stair slab

| Yam ntxwv | Tus nqi | Kuaj |

| Ceev: | +/- 1030 kg/m3 | EN 14342: 2005 + A1: 2008 |

| Brinell hardness: | 9.5 kg/m² | TS EN 1534: 2010 |

| Cov dej noo: | 8.3% ntawm 23 ° C thiab 50% txheeb ze humidity | TS EN 1534: 2010 |

| Emission chav kawm: | Chav Kawm E1 (LT 0,124 mg / m3, EN 717-1) | TS EN 717-1 |

| Differential o o: | 0.17% pro 1% hloov hauv cov ntsiab lus noo noo | TS EN 14341: 2005 |

| Abrasion tsis kam: | 16,000 teev | EN-14354 (12/16) |

| Compressability: | PEB 2930 kN/cm2 | TS EN ISO 2409 1 |

| Impact resistance: | 6 hli | TS EN 14354-1 |

| Cov khoom hluav taws kub: | Chav Kawm Cfl-s1 (EN 13501-1) | TS EN 13501-1 |